- Have any questions?

- +92 370 5961 297

- info@migcindustries.com

Years of Industry Expertise

Successful Projects Delivered

Customer Satisfaction Guaranteed

At MIGC Industries Pakistan, we specialize in providing high-quality chemical solutions and engineering services. From industrial raw materials to complete turnkey plant engineering, we cater to diverse industry needs with a focus on quality, innovation, and environmental sustainability. Partner with us to achieve unmatched excellence and reliability in chemical sourcing and engineering solutions.

We provide a comprehensive range of high-quality raw materials tailored to meet the demands of various industries.

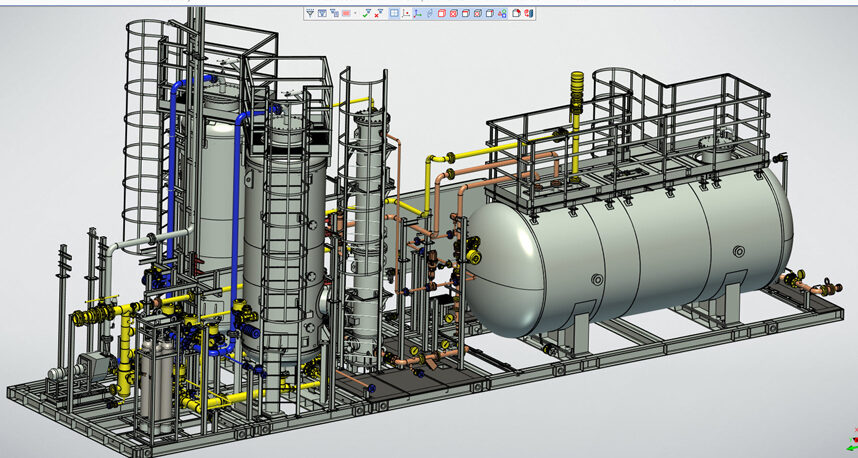

At MIGC Industries, we provide comprehensive turnkey solutions for the design, construction, and commissioning of chemical plants. Our services include

MIGC Industries stands as a beacon of innovation and expertise in the global chemical and industrial manufacturing sectors. With a legacy of excellence and a commitment to technological advancement, we deliver cutting-edge solutions across a wide array of domains, including chemical production plants, plasticizers, stabilizers, green recycling projects, and more. Our team of experts, equipped with German technology and decades of experience, ensures that each project meets the highest standards of quality, sustainability, and efficiency.

we are dedicated to fostering sustainable practices by delivering advanced Green Project Solutions in plastic waste recycling and lysine sulfate production. Our expertise extends to cutting-edge technologies for chemical recycling, mechanical recycling, and closed-loop recycling processes, as well as the production of lysine sulfate 70% feed grade and pharmaceutical-grade lysine.

At MIGC Industries, we supply a comprehensive range of industrial chemicals tailored to meet the diverse needs of various industries. Our commitment to quality ensures that each product delivers optimal performance and reliability. Our product offerings include:

We provide a comprehensive range of high-quality raw materials tailored to meet the demands of various industries. Our offerings include:

To be a global leader in the chemical and engineering industry, recognized for innovation, sustainability, and excellence in delivering solutions that empower industries and transform communities.

To provide world-class chemical products and turnkey engineering services that meet the highest standards of quality, sustainability, and customer satisfaction, fostering growth and innovation across diverse industries.

Driving industrial progress by offering cutting-edge solutions, building lasting relationships, and ensuring a sustainable future through quality, innovation, and commitment to excellence.

Welcome to MIGC Industries Pakistan!

At MIGC, we are committed to delivering excellence in every aspect of our business. Our journey has been fueled by innovation, collaboration, and an unwavering dedication to meeting the needs of our clients across industries. With a focus on quality, sustainability, and cutting-edge technology, we strive to empower businesses with the tools and solutions they need to succeed in today’s competitive landscape.

Our dual approach—offering premium industrial raw materials and providing turnkey solutions for chemical plant engineering—ensures that we cater to the unique requirements of a diverse clientele. We believe in building lasting relationships, fostering trust, and driving mutual growth.

Thank you for choosing MIGC Industries as your partner. Together, let’s pave the way for a brighter, more innovative future.

Warm regards,

*Faisal Iqbal*

Director of Operations

MIGC Industries Pakistan

LAHORE OFFICE :

Address: 1st Floor, MIGC Heights, 3200 Empress Rd, near Carlton Tower Hotel, opposite to Tabligh-ul-Quran (Welfare Trust, Garhi Shahu, Lahore, Punjab 54000

KARACHI OFFICE:

Address: 09 Beaumont Rd, Civil Lines Kashmir Mujahid Colony, Karachi, Karachi City, Sindh 74400

MOBILE/WHATSAPP: +92 370 5961 297

EMAIL: faisaliqbal20162016@gmail.com

EMAIL: info@migcindustries.com

At MIGC Industries Pakistan, we specialize in providing high-quality chemical solutions and engineering services. From industrial raw materials to complete turnkey plant engineering, we cater to diverse industry needs with a focus on quality, innovation, and environmental sustainability. Partner with us to achieve unmatched excellence and reliability in chemical sourcing and engineering solutions.

Get The Latest Updates via email. Any time you may unsubscribe

Migc Industries invests heavily in research to improve existing chemical processes and develop new, more efficient production methods. We collaborate with leading experts in the chemical engineering field, universities, and industry professionals to stay at the forefront of technological advancements

Get The Latest Updates via email. Any time you may unsubscribe